How to improve the safety of underground cable laying by using MPP power cable protection tube?

Release Time : 2025-04-24

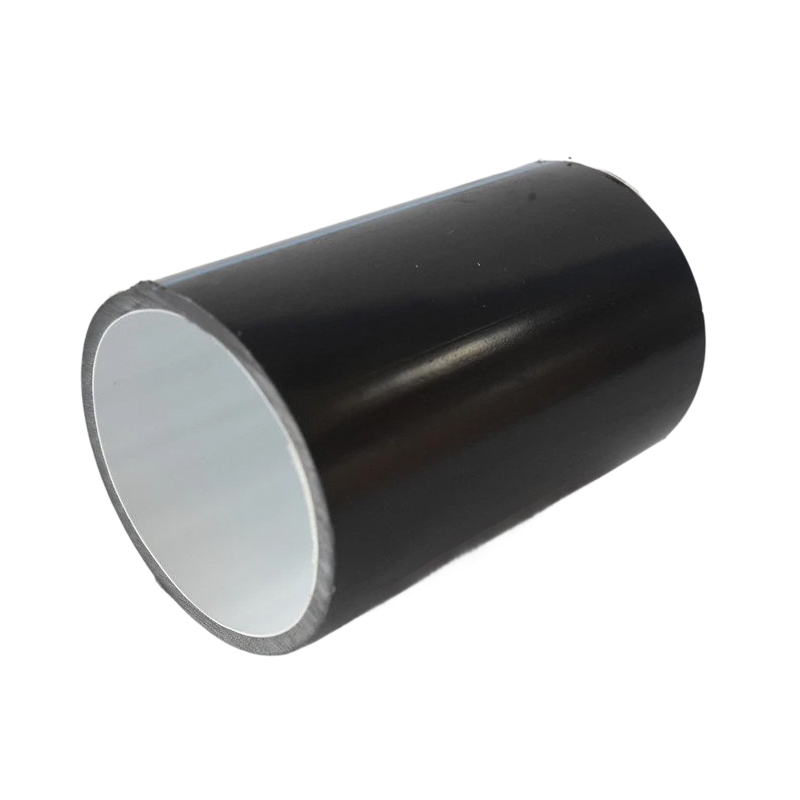

With the accelerating urbanization process, underground cable laying has become a key link in ensuring the power supply of cities. However, the underground environment is complex and changeable, and cables face many safety hazards during the laying process and subsequent operation. In order to ensure the safe and stable operation of power cables, MPP power cable protection tube came into being, and with its unique advantages, it plays an important role in improving the safety of underground cable laying.

1. Advantages of MPP power cable protection tube

High strength and corrosion resistance: MPP power cable protection tube uses modified polypropylene as the main raw material. This material has extremely high mechanical strength and excellent corrosion resistance. It can withstand the erosion of underground soil, moisture and chemicals, ensuring the long-term and stable operation of cables in harsh environments.

Good insulation performance: MPP power cable protection tube has good electrical insulation performance, which can effectively prevent current leakage and reduce the safety hazards caused by current leakage. This is crucial to ensure the safe operation of power cables.

Convenient construction and environmental protection: MPP power cable protection tube is light and easy to process. During the construction process, there is no need for a large amount of dredging, excavation and road damage, which meets the environmental protection requirements of modern urban construction. At the same time, its installation is simple and quick, which can greatly shorten the construction period and reduce construction costs.

2. Application of MPP power cable protection tube in improving safety

Prevent external force damage: During the laying process and subsequent operation, underground cables may be damaged by external forces such as construction excavation and vehicle rolling. The high strength and corrosion resistance of MPP power cable protection tube can effectively resist the impact of these external forces and protect the cables from damage.

Prevent chemical corrosion: There may be various chemical substances in the underground environment, such as acid, alkali, oil, etc., which pose a serious threat to the insulation layer of the cable. The corrosion resistance of MPP power cable protection tube can effectively isolate these chemicals from erosion of the cable and ensure that the insulation performance of the cable is not affected.

Prevent moisture intrusion: The underground environment is humid, and moisture can easily invade the inside of the cable, resulting in a decrease in the insulation performance of the cable and even causing a short circuit accident. MPP power cable protection tube has good sealing performance, which can effectively prevent moisture from invading the inside of the cable and ensure the safe operation of the cable.

Improve the heat dissipation performance of the cable: The inner wall of the MPP power cable protection tube is smooth, and the contact surface with the cable is small, which is conducive to the heat dissipation of the cable. This helps to reduce the temperature of the cable during operation, extend the service life of the cable, and reduce the safety hazards caused by overheating of the cable.

3. Construction and maintenance of MPP power cable protection tube

During the construction of the MPP power cable protection tube, it is necessary to strictly follow the relevant specifications. First, it is necessary to ensure that the quality of the pipe meets the standards and there are no defects such as bubbles and cracks in the appearance. Secondly, when connecting the pipes, special connectors or hot-melt connections should be used to ensure good sealing at the joints to prevent moisture from infiltrating. In addition, during the backfilling process, excessive pressure or damage to the pipeline should be avoided to ensure the integrity of the pipeline.

In terms of maintenance, the MPP power cable protection tube should be inspected regularly, including appearance inspection, joint sealing inspection, etc. If the pipeline is found to be damaged or aging, it should be repaired or replaced in time to ensure the safe operation of the cable.

MPP power cable protection tube plays an important role in improving the safety of underground cable laying with its advantages such as high strength, corrosion resistance, good insulation performance and construction convenience.

1. Advantages of MPP power cable protection tube

High strength and corrosion resistance: MPP power cable protection tube uses modified polypropylene as the main raw material. This material has extremely high mechanical strength and excellent corrosion resistance. It can withstand the erosion of underground soil, moisture and chemicals, ensuring the long-term and stable operation of cables in harsh environments.

Good insulation performance: MPP power cable protection tube has good electrical insulation performance, which can effectively prevent current leakage and reduce the safety hazards caused by current leakage. This is crucial to ensure the safe operation of power cables.

Convenient construction and environmental protection: MPP power cable protection tube is light and easy to process. During the construction process, there is no need for a large amount of dredging, excavation and road damage, which meets the environmental protection requirements of modern urban construction. At the same time, its installation is simple and quick, which can greatly shorten the construction period and reduce construction costs.

2. Application of MPP power cable protection tube in improving safety

Prevent external force damage: During the laying process and subsequent operation, underground cables may be damaged by external forces such as construction excavation and vehicle rolling. The high strength and corrosion resistance of MPP power cable protection tube can effectively resist the impact of these external forces and protect the cables from damage.

Prevent chemical corrosion: There may be various chemical substances in the underground environment, such as acid, alkali, oil, etc., which pose a serious threat to the insulation layer of the cable. The corrosion resistance of MPP power cable protection tube can effectively isolate these chemicals from erosion of the cable and ensure that the insulation performance of the cable is not affected.

Prevent moisture intrusion: The underground environment is humid, and moisture can easily invade the inside of the cable, resulting in a decrease in the insulation performance of the cable and even causing a short circuit accident. MPP power cable protection tube has good sealing performance, which can effectively prevent moisture from invading the inside of the cable and ensure the safe operation of the cable.

Improve the heat dissipation performance of the cable: The inner wall of the MPP power cable protection tube is smooth, and the contact surface with the cable is small, which is conducive to the heat dissipation of the cable. This helps to reduce the temperature of the cable during operation, extend the service life of the cable, and reduce the safety hazards caused by overheating of the cable.

3. Construction and maintenance of MPP power cable protection tube

During the construction of the MPP power cable protection tube, it is necessary to strictly follow the relevant specifications. First, it is necessary to ensure that the quality of the pipe meets the standards and there are no defects such as bubbles and cracks in the appearance. Secondly, when connecting the pipes, special connectors or hot-melt connections should be used to ensure good sealing at the joints to prevent moisture from infiltrating. In addition, during the backfilling process, excessive pressure or damage to the pipeline should be avoided to ensure the integrity of the pipeline.

In terms of maintenance, the MPP power cable protection tube should be inspected regularly, including appearance inspection, joint sealing inspection, etc. If the pipeline is found to be damaged or aging, it should be repaired or replaced in time to ensure the safe operation of the cable.

MPP power cable protection tube plays an important role in improving the safety of underground cable laying with its advantages such as high strength, corrosion resistance, good insulation performance and construction convenience.