How does silicon core tube improve sealing performance through its unique inner wall coating?

Release Time : 2025-07-16

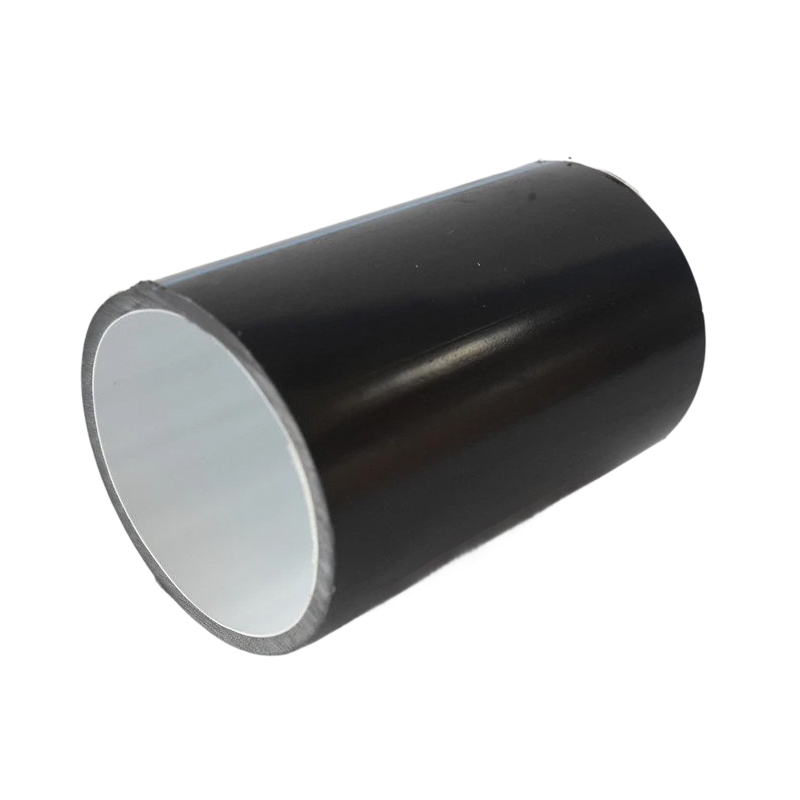

As a new type of composite pipe, silicon core tube plays a vital role in modern communication network systems. Its uniqueness lies in the fact that the inner wall is coated with silicone solid lubricant. This design not only significantly reduces the friction coefficient, but also greatly improves the sealing performance of the pipe. In this way, silicon core tube can ensure that the optical cable remains in the best condition during installation and long-term use, providing a solid guarantee for the efficient operation of the communication network system.

First of all, the inner wall coating of silicon core tube uses silicone solid lubricant, which has excellent lubricity and chemical stability. During the manufacturing process, this layer of lubricant is evenly applied to the inner wall of the pipe to form a dense and smooth protective film. This film not only reduces the friction between the optical cable and the inner wall of the pipe, but also effectively prevents external impurities from entering the pipe, thereby improving the overall sealing performance. Because the silicone solid lubricant has an extremely low friction coefficient, the optical cable can pass through the pipe more smoothly during laying, reducing the risk of wear and damage caused by friction.

Secondly, the inner wall coating of silicon core tube not only provides excellent lubrication, but also enhances the sealing of the pipeline to a certain extent. When the optical cable is pushed or pulled into the pipeline, the lubricant coating fills the tiny unevenness on the inner wall of the pipeline to form a nearly perfect smooth surface. In this way, even if the pipeline is slightly deformed or squeezed during construction, it can ensure a close fit between the optical cable and the pipeline, further improving the sealing effect. In addition, this coating also has a certain self-repairing function, that is, it can still maintain a good sealing state after being partially damaged, avoiding potential leakage hazards.

Furthermore, the sealing performance of silicon core tube also benefits from the superior properties of its material itself. High-density polyethylene (HDPE) as the main raw material gives silicon core tube excellent flexibility and strength. HDPE material not only has good corrosion resistance and aging resistance, but also maintains stable physical properties over a wide temperature range. These characteristics enable silicon core tube to maintain a good sealing effect in the face of different environmental conditions. Especially in underground laying environments, moisture, chemicals and microorganisms in the soil may cause erosion to the pipeline, and the double protection of HDPE material combined with silicone coating effectively resists the influence of these external factors and ensures the long-term sealing of the pipeline.

Not only that, the design of silicon core tube takes into account various challenges in the actual construction process. For example, in the process of laying long-distance optical cables, traditional pipelines may fail to seal due to improper handling of joints. However, silicon core tube adopts advanced connection technology, so that the joints between pipelines also have excellent sealing performance. Through special joint design and the application of sealing materials, silicon core tube can form a seamless connection at the connection part to prevent the intrusion of external moisture and other impurities. At the same time, this design also simplifies the construction process, reduces the difficulty of on-site operations, and improves work efficiency.

In addition, the inner wall coating of silicon core tube also has certain antistatic properties. During the laying of optical cables, static electricity accumulation may lead to dust adsorption or other safety hazards. The antistatic properties of silicone solid lubricants can effectively reduce the generation of static electricity and keep the inner wall of the pipeline clean and dust-free. This not only helps to improve the quality of optical cable laying, but also helps to extend the service life of pipelines and optical cables. A clean inner wall environment is essential for maintaining the sealing inside the pipeline, because the presence of any foreign matter may destroy the original sealing structure and affect the overall performance of the pipeline.

It is worth mentioning that the sealing performance of silicon core tube is not only reflected in the initial installation stage, but also in its long-term stable performance. After long-term use, ordinary pipelines may have problems such as aging and cracking, resulting in a decrease in sealing performance. However, with its high-quality raw materials and special coatings, silicon core tube can continue to provide reliable sealing protection for many years or even decades. Whether facing daily temperature and humidity changes or the test under extreme weather conditions, silicon core tube can perform well, always maintain a high degree of sealing, and ensure the normal operation of the optical cable communication network system.

Finally, the sealing performance of silicon core tube is crucial to the security and reliability of the entire communication network. Once a pipeline leaks, it will not only affect the transmission quality of the optical cable, but may also cause communication interruption, causing inconvenience and even economic losses to users. Therefore, silicon core tube provides solid support for the construction of communication infrastructure with its excellent sealing performance. It can not only adapt to complex and changeable geological conditions and harsh natural environments, but also effectively cope with various uncertainties during the construction process, becoming an indispensable part of modern communication networks.

In summary, silicon core tube significantly improves the sealing performance of the pipeline through its unique inner wall coating-organic silicone solid lubricant. This design not only optimizes the friction coefficient during the laying of optical cables, but also enhances the overall sealing of the pipeline, ensuring the long-term reliable operation of the communication network system. Whether in terms of installation convenience, durability or environmental protection, silicon core tube has demonstrated unparalleled advantages, injecting new vitality into the development of modern communication infrastructure.

First of all, the inner wall coating of silicon core tube uses silicone solid lubricant, which has excellent lubricity and chemical stability. During the manufacturing process, this layer of lubricant is evenly applied to the inner wall of the pipe to form a dense and smooth protective film. This film not only reduces the friction between the optical cable and the inner wall of the pipe, but also effectively prevents external impurities from entering the pipe, thereby improving the overall sealing performance. Because the silicone solid lubricant has an extremely low friction coefficient, the optical cable can pass through the pipe more smoothly during laying, reducing the risk of wear and damage caused by friction.

Secondly, the inner wall coating of silicon core tube not only provides excellent lubrication, but also enhances the sealing of the pipeline to a certain extent. When the optical cable is pushed or pulled into the pipeline, the lubricant coating fills the tiny unevenness on the inner wall of the pipeline to form a nearly perfect smooth surface. In this way, even if the pipeline is slightly deformed or squeezed during construction, it can ensure a close fit between the optical cable and the pipeline, further improving the sealing effect. In addition, this coating also has a certain self-repairing function, that is, it can still maintain a good sealing state after being partially damaged, avoiding potential leakage hazards.

Furthermore, the sealing performance of silicon core tube also benefits from the superior properties of its material itself. High-density polyethylene (HDPE) as the main raw material gives silicon core tube excellent flexibility and strength. HDPE material not only has good corrosion resistance and aging resistance, but also maintains stable physical properties over a wide temperature range. These characteristics enable silicon core tube to maintain a good sealing effect in the face of different environmental conditions. Especially in underground laying environments, moisture, chemicals and microorganisms in the soil may cause erosion to the pipeline, and the double protection of HDPE material combined with silicone coating effectively resists the influence of these external factors and ensures the long-term sealing of the pipeline.

Not only that, the design of silicon core tube takes into account various challenges in the actual construction process. For example, in the process of laying long-distance optical cables, traditional pipelines may fail to seal due to improper handling of joints. However, silicon core tube adopts advanced connection technology, so that the joints between pipelines also have excellent sealing performance. Through special joint design and the application of sealing materials, silicon core tube can form a seamless connection at the connection part to prevent the intrusion of external moisture and other impurities. At the same time, this design also simplifies the construction process, reduces the difficulty of on-site operations, and improves work efficiency.

In addition, the inner wall coating of silicon core tube also has certain antistatic properties. During the laying of optical cables, static electricity accumulation may lead to dust adsorption or other safety hazards. The antistatic properties of silicone solid lubricants can effectively reduce the generation of static electricity and keep the inner wall of the pipeline clean and dust-free. This not only helps to improve the quality of optical cable laying, but also helps to extend the service life of pipelines and optical cables. A clean inner wall environment is essential for maintaining the sealing inside the pipeline, because the presence of any foreign matter may destroy the original sealing structure and affect the overall performance of the pipeline.

It is worth mentioning that the sealing performance of silicon core tube is not only reflected in the initial installation stage, but also in its long-term stable performance. After long-term use, ordinary pipelines may have problems such as aging and cracking, resulting in a decrease in sealing performance. However, with its high-quality raw materials and special coatings, silicon core tube can continue to provide reliable sealing protection for many years or even decades. Whether facing daily temperature and humidity changes or the test under extreme weather conditions, silicon core tube can perform well, always maintain a high degree of sealing, and ensure the normal operation of the optical cable communication network system.

Finally, the sealing performance of silicon core tube is crucial to the security and reliability of the entire communication network. Once a pipeline leaks, it will not only affect the transmission quality of the optical cable, but may also cause communication interruption, causing inconvenience and even economic losses to users. Therefore, silicon core tube provides solid support for the construction of communication infrastructure with its excellent sealing performance. It can not only adapt to complex and changeable geological conditions and harsh natural environments, but also effectively cope with various uncertainties during the construction process, becoming an indispensable part of modern communication networks.

In summary, silicon core tube significantly improves the sealing performance of the pipeline through its unique inner wall coating-organic silicone solid lubricant. This design not only optimizes the friction coefficient during the laying of optical cables, but also enhances the overall sealing of the pipeline, ensuring the long-term reliable operation of the communication network system. Whether in terms of installation convenience, durability or environmental protection, silicon core tube has demonstrated unparalleled advantages, injecting new vitality into the development of modern communication infrastructure.