How does the silicon core tube ensure the uniformity and adhesion of the inner silicone layer through a three-layer co-extrusion process?

Release Time : 2025-09-24

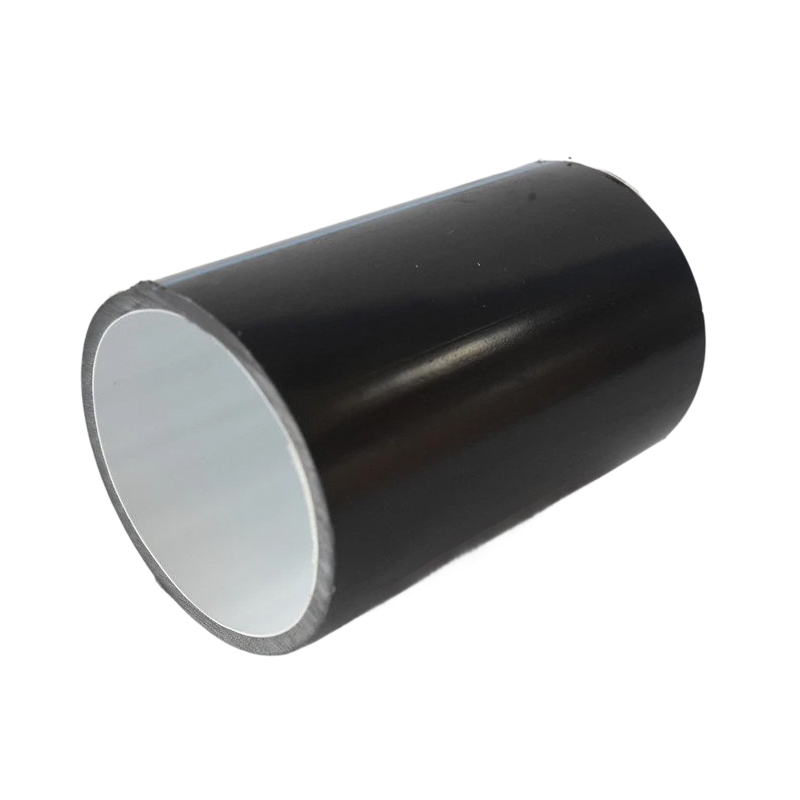

In the construction of modern optical cable communication networks, silicon core tubes serve as the "blood vessels" through which optical cables pass, and their performance is directly related to the laying efficiency and long-term operational reliability. Its core advantage lies in the silicone-based solid lubricant coating on its inner wall. This material has an extremely low coefficient of friction, significantly reducing resistance when the optical fiber travels long distances. However, if this lubricant layer is unevenly distributed or poorly adhered, it not only weakens the lubrication effect but may also cause scratches on the optical fiber or blockages in the tube. Therefore, ensuring the uniformity and adhesion of the silicone layer becomes a key challenge in silicon core tube manufacturing. This is achieved through a precise three-layer co-extrusion process, integrating material science and engineering control to simultaneously form multiple layers of material under high temperature and pressure.

The core of the three-layer co-extrusion process lies in its synchronization. High-density polyethylene (HDPE) serves as the main material for the outer and middle layers, providing mechanical strength, weather resistance, and pressure resistance. The silicone acts as the functional material for the inner layer, imparting its low-friction properties. These three materials are separately heated and melted by three independent extruders. A precise metering system controls the flow rate, ensuring that each layer of material enters the composite die head at a constant ratio. Any fluctuation in flow rate or temperature deviation from any extruder can disrupt the layer ratio, affecting the final structure. Therefore, equipment stability and control system accuracy are critical.

The composite die head is the heart of the entire process. It does not simply stack the three layers; rather, its precise internal channel design ensures that the molten HDPE and silicone form an ordered layered structure before entering the die cavity. The outer HDPE adheres to the die wall, forming the outer wall of the tube; the middle HDPE then wraps around it, forming the main support; and the innermost silicone material is precisely guided to the center, uniformly coating the inner surface of the middle layer under high pressure. This dynamic coating process requires a high degree of matching between material viscosity, flow rate, and pressure, ensuring a uniform, thin silicone layer without any accumulation or gaps. The adhesion strength is achieved through a physical bond at the molecular level, realized under high-temperature melt conditions, without relying on adhesives or post-processing. When the silicone and the inner HDPE layer are both in a molten state, the molecular chains of the two materials partially entangle and interpenetrate at the interface, forming a strong bond upon cooling. This bond strength far surpasses simple physical adsorption, resisting abrasion during cable installation and environmental stresses during long-term use. Furthermore, the surface energy of the HDPE material is optimized to enhance compatibility with the silicone, further strengthening the bond.

Temperature control is crucial throughout the extrusion process. Too low a temperature results in poor material flow and uneven distribution; too high a temperature can cause silicone degradation or HDPE oxidation, affecting material properties. Therefore, each extruder and die head temperature zone is precisely set and continuously monitored to ensure optimal conditions for material compounding.

The cooling and shaping stage also impacts the final quality. After extrusion, the pipe immediately enters a vacuum shaping tank and a spray cooling system. The cooling process must be gradual and uniform to avoid internal stress or deformation due to excessive temperature differences. Rapid cooling can cause micro-cracks or delamination in the silicone layer due to uneven shrinkage. Multi-stage gradient cooling ensures gradual solidification, maintaining the pipe's roundness and smooth inner wall.

Ultimately, the three-layer co-extrusion process is a highly coordinated manufacturing art in both time and space. It seamlessly integrates materials with different properties, preserving their individual functions while forming an inseparable whole. When the inner wall of each meter of silicon core tube is covered with a uniform and firm silicone layer, the optical cable can pass smoothly through it, spanning mountains and cities. This precise control, hidden within the process, is the silent guarantee of the efficient and reliable operation of modern communication infrastructure.