What quality defects can result from improper control of the heat fusion temperature during PE pipe connection?

Release Time : 2025-12-03

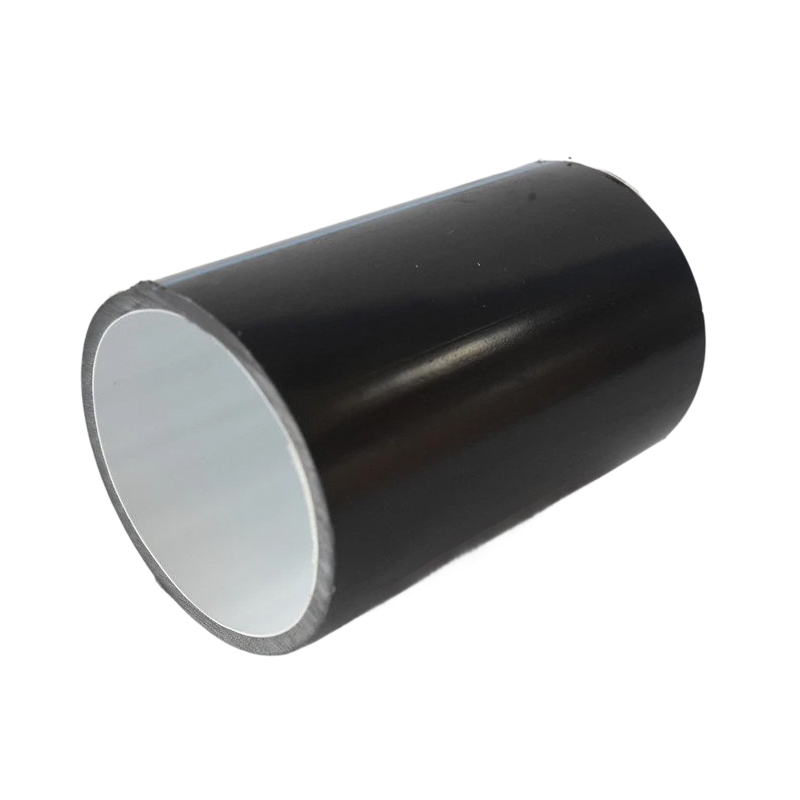

When connecting PE pipes, controlling the heat fusion temperature is crucial for ensuring weld quality, directly impacting the piping system's sealing, strength, and long-term operational stability. If the temperature deviates from the appropriate range, whether too low or too high, it will trigger a series of quality defects. These defects not only affect pipe performance but may also create safety hazards.

When the heat fusion temperature is too low, the PE pipe end faces cannot fully melt, and the molecular chains fail to reach an effective active state, resulting in insufficient penetration at the weld surface. At this time, the molten layer on both sides of the pipe cannot form a uniform molecular interwoven structure, significantly reducing the connection strength. Under pressure or temperature changes, tiny gaps easily appear at the weak weld areas, becoming leakage channels. Initially, this defect may only manifest as localized wetting, but with continued media penetration, it will gradually develop into a significant leak, especially in water or gas pipelines, potentially leading to resource waste or safety accidents.

If the heat fusion temperature is too high, the PE material will face the risk of thermal degradation. When the temperature exceeds the critical point for molecular chain breakage, polyethylene molecules will carbonize, causing a sharp decrease in material strength. High temperatures can also cause excessive softening of the pipe end face, expanding the molten zone and resulting in excessively large flanges or weld heights. This structure not only artificially reduces the water flow cross-section and lowers the designed flow rate, but also increases the brittleness of the carbonized layer, making it prone to crack propagation during subsequent use. Furthermore, in high-temperature environments, prolonged heating can lead to the formation of an oxide layer on the pipe surface, further weakening molecular entanglement and accelerating joint aging.

Improper temperature control can also cause welding defects. For example, the presence of stains or foreign matter on the weld end face can cause uneven heating, leading to wall thickness deviations on both sides, asymmetry around the weld joint, and the appearance of cuts or gaps. If the pipe's ellipticity does not meet standards, misalignment is likely to occur during alignment, reducing connection reliability. Misalignment of the fixture stroke or uncontrolled temperature and pressure parameters during the melting stage can also cause abnormal weld geometry, such as excessive height or width. These defects alter fluid dynamics, increase local resistance, and may even induce eddies, accelerating pipe wear.

At the microscopic level, temperature fluctuations directly affect weld penetration. If the pipe ends are not parallel, or the heating plate does not fully weld the ends, incomplete fusion areas will form, creating internal cracks or potential for further breakage. These defects are difficult to detect during routine inspections but will gradually become apparent over long-term use due to changes in medium pressure or temperature, leading to sudden leaks. Furthermore, differences in the quality of the hot melt or deviations in flow rate can exacerbate the risk of microscopic defects. When the flow rate deviation exceeds a certain range, the quality of the pipe joint will significantly decrease, creating localized weak points.

The synergistic effect of environmental factors and temperature control is also crucial. During construction in low-temperature environments, failure to dynamically adjust welding parameters according to the ambient temperature can easily result in "intercalated welds." For example, conventional welding temperatures at low temperatures may cause the pipe surface to melt but the interior to not fully penetrate, significantly reducing compressive strength. In this case, even if the surface is well-formed, unfused areas remain internally, becoming potential failure points.

To avoid these defects, comprehensive quality control must be implemented throughout the entire welding process—before, during, and after welding. Before welding, ensure the pipe end faces are clean and dry, and that the ovality meets standards. Use heat fusion equipment with automatic compensation capabilities. During welding, strictly monitor temperature, pressure, and time parameters, and avoid interference from ambient wind speed or temperature fluctuations. After welding, verify the connection quality through visual inspection, sample removal, and pressure testing. Scientific parameter adjustment and meticulous operation can effectively ensure the reliability of PE pipe heat fusion connections, laying the foundation for the long-term stable operation of the pipeline system.