How is the advantage of PE pipe's light weight reflected in the process of transportation and handling?

Release Time : 2025-06-05

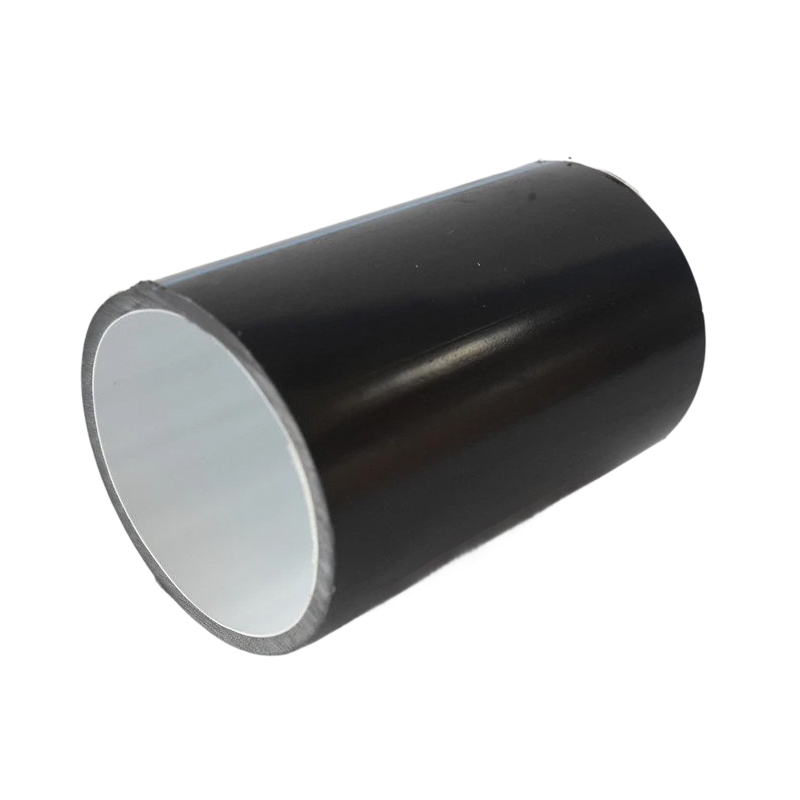

PE pipe (polyethylene pipe) has shown significant advantages in the process of transportation and handling due to its light weight, providing great convenience for various engineering projects. This feature not only simplifies the construction process, but also reduces labor intensity and cost, and improves overall work efficiency.

First of all, the light weight of PE pipe means that the load of the transport vehicle can be significantly reduced during transportation. Compared with traditional metal pipes such as steel pipes or cast iron pipes, PE pipe is much lighter, which allows more pipe materials to be loaded on the same truck. There is no need to add additional transport vehicles or frequently travel between the construction site and the warehouse, which greatly saves logistics costs. In addition, the lighter weight also reduces the pressure on road infrastructure and reduces the risk of wear and tear during transportation, which is especially beneficial for long-distance transportation.

Secondly, the lightweight design of PE pipe greatly facilitates on-site handling. In construction sites, municipal projects or agricultural irrigation systems, the construction site is often complex in terrain, limited in space, and sometimes requires crossing obstacles for installation. Due to the light weight of PE pipe, a single person or a few workers can easily carry and position it without relying on heavy machinery assistance. This feature not only improves construction flexibility, but also reduces the need for large mechanical equipment, thereby reducing the equipment rental costs and operational complexity of the project.

In addition, the ease of manual operation of PE pipe is also a highlight. Whether it is horizontally laid or vertically installed, workers can work relatively easily. Especially when working in a small space, the lightness of PE pipe enables workers to complete the task without sacrificing efficiency. For example, when laying pipes in the basement or ceiling, lightweight PE pipes can be quickly and accurately placed in place, avoiding installation difficulties caused by excessively heavy pipes. At the same time, this also reduces manual fatigue, improves work efficiency, and helps maintain high-quality work standards.

It is worth mentioning that PE pipe also shows convenience in the connection link. Because of its soft material and light weight, workers can more easily adjust the position of the pipe to ensure perfect docking at the interface. Whether it is hot-melt or electric-melt connection, the lightweight PE pipe allows workers to complete the connection work with less effort and time, improving the sealing and reliability of the entire system. In addition, lightweight PE pipe is also particularly suitable for high-altitude operations or hanging installations, reducing the risk of falling objects from high altitudes and ensuring the safety of construction workers.

In addition, the lightweight of PE pipe also brings convenience in storage. In warehouses or temporary storage points, PE pipe occupies relatively small space and is easy to stack and manage. Compared with bulky traditional pipes, PE pipe can be stacked in layers without damaging the lower pipes, which effectively utilizes the storage space. This efficient storage method not only reduces the floor space, but also provides the possibility of rapid call in emergency situations, further improving the emergency response capability.

In addition, the light weight of PE pipe also helps to reduce energy consumption during construction. Whether it is the fuel consumption of transportation vehicles or the power consumption of electric tools used on construction sites, the application of lightweight materials can play a certain energy-saving effect. With the increasing global attention to sustainable development, choosing PE pipe as a pipeline material is not only in line with the concept of green building, but also can bring economic benefits and social reputation to enterprises.

Finally, the lightweight characteristics of PE pipe are particularly prominent in dealing with emergencies. For example, in the reconstruction work after natural disasters, the rapid restoration of water and gas supply systems is one of the top priorities. Because PE pipe is easy to carry and install, rescue teams can transport the necessary pipes to the disaster-stricken areas in the shortest time and quickly carry out repair work. This flexibility and efficiency are essential for post-disaster reconstruction and help restore normal life as soon as possible.

In summary, the advantages of PE pipe's light weight are fully reflected in the transportation and handling process. From reducing transportation costs to improving on-site operation efficiency, from reducing labor burden to optimizing warehouse management, to supporting rapid emergency response, PE pipe provides all-round support for modern engineering construction with its lightweight characteristics. Whether it is a new project or a renovation project, PE pipe is a trustworthy choice, and it will continue to promote infrastructure construction in a more efficient and environmentally friendly direction worldwide. For enterprises and institutions that pursue high quality, low cost and sustainability, PE pipe is undoubtedly one of the best pipeline solutions.

First of all, the light weight of PE pipe means that the load of the transport vehicle can be significantly reduced during transportation. Compared with traditional metal pipes such as steel pipes or cast iron pipes, PE pipe is much lighter, which allows more pipe materials to be loaded on the same truck. There is no need to add additional transport vehicles or frequently travel between the construction site and the warehouse, which greatly saves logistics costs. In addition, the lighter weight also reduces the pressure on road infrastructure and reduces the risk of wear and tear during transportation, which is especially beneficial for long-distance transportation.

Secondly, the lightweight design of PE pipe greatly facilitates on-site handling. In construction sites, municipal projects or agricultural irrigation systems, the construction site is often complex in terrain, limited in space, and sometimes requires crossing obstacles for installation. Due to the light weight of PE pipe, a single person or a few workers can easily carry and position it without relying on heavy machinery assistance. This feature not only improves construction flexibility, but also reduces the need for large mechanical equipment, thereby reducing the equipment rental costs and operational complexity of the project.

In addition, the ease of manual operation of PE pipe is also a highlight. Whether it is horizontally laid or vertically installed, workers can work relatively easily. Especially when working in a small space, the lightness of PE pipe enables workers to complete the task without sacrificing efficiency. For example, when laying pipes in the basement or ceiling, lightweight PE pipes can be quickly and accurately placed in place, avoiding installation difficulties caused by excessively heavy pipes. At the same time, this also reduces manual fatigue, improves work efficiency, and helps maintain high-quality work standards.

It is worth mentioning that PE pipe also shows convenience in the connection link. Because of its soft material and light weight, workers can more easily adjust the position of the pipe to ensure perfect docking at the interface. Whether it is hot-melt or electric-melt connection, the lightweight PE pipe allows workers to complete the connection work with less effort and time, improving the sealing and reliability of the entire system. In addition, lightweight PE pipe is also particularly suitable for high-altitude operations or hanging installations, reducing the risk of falling objects from high altitudes and ensuring the safety of construction workers.

In addition, the lightweight of PE pipe also brings convenience in storage. In warehouses or temporary storage points, PE pipe occupies relatively small space and is easy to stack and manage. Compared with bulky traditional pipes, PE pipe can be stacked in layers without damaging the lower pipes, which effectively utilizes the storage space. This efficient storage method not only reduces the floor space, but also provides the possibility of rapid call in emergency situations, further improving the emergency response capability.

In addition, the light weight of PE pipe also helps to reduce energy consumption during construction. Whether it is the fuel consumption of transportation vehicles or the power consumption of electric tools used on construction sites, the application of lightweight materials can play a certain energy-saving effect. With the increasing global attention to sustainable development, choosing PE pipe as a pipeline material is not only in line with the concept of green building, but also can bring economic benefits and social reputation to enterprises.

Finally, the lightweight characteristics of PE pipe are particularly prominent in dealing with emergencies. For example, in the reconstruction work after natural disasters, the rapid restoration of water and gas supply systems is one of the top priorities. Because PE pipe is easy to carry and install, rescue teams can transport the necessary pipes to the disaster-stricken areas in the shortest time and quickly carry out repair work. This flexibility and efficiency are essential for post-disaster reconstruction and help restore normal life as soon as possible.

In summary, the advantages of PE pipe's light weight are fully reflected in the transportation and handling process. From reducing transportation costs to improving on-site operation efficiency, from reducing labor burden to optimizing warehouse management, to supporting rapid emergency response, PE pipe provides all-round support for modern engineering construction with its lightweight characteristics. Whether it is a new project or a renovation project, PE pipe is a trustworthy choice, and it will continue to promote infrastructure construction in a more efficient and environmentally friendly direction worldwide. For enterprises and institutions that pursue high quality, low cost and sustainability, PE pipe is undoubtedly one of the best pipeline solutions.