Why can silicon core tube maintain good sealing in complex environments?

Release Time : 2025-06-18

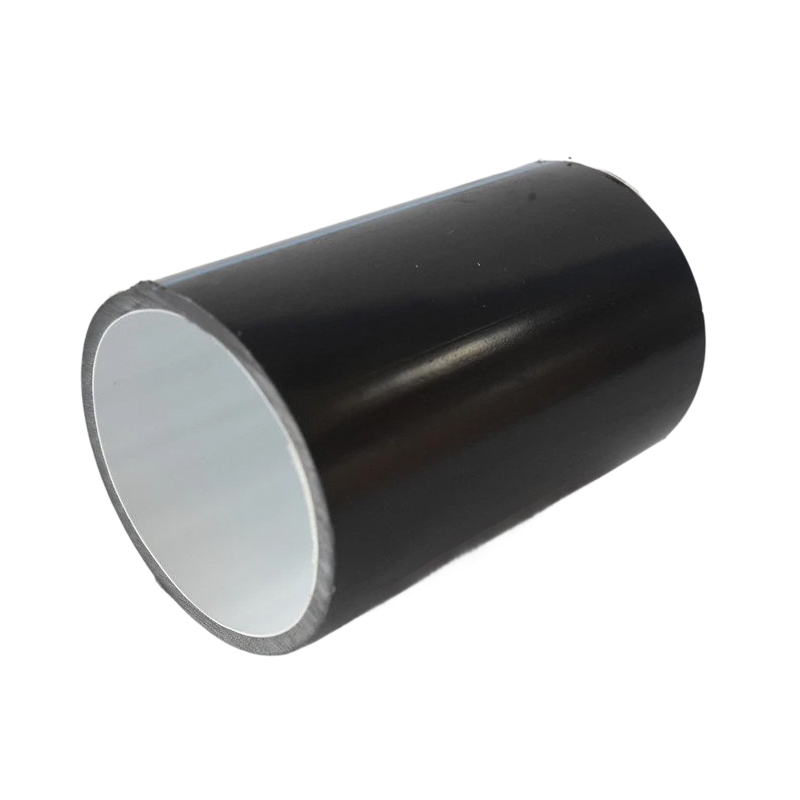

In the construction of modern communication infrastructure, the performance of optical cable pipelines as the "blood vessels" for information transmission is directly related to the stability and security of the entire network system. As a new type of composite pipeline material, silicon core tube is widely used in optical cable communication network systems in complex environments such as roads and railways due to its excellent sealing performance, chemical corrosion resistance and economic and practical characteristics.

1. Structural design lays the foundation for sealing performance

Silicon core tube adopts a three-layer co-extrusion composite structure, which is extruded synchronously by three plastic extruders. The outer layer and the middle layer are mainly made of high-density polyethylene (HDPE), which has good mechanical strength and compressive resistance; while the inner layer is coated with a layer of organic silicon solid lubricant, which not only reduces the friction coefficient, but also enhances the density of the inside of the pipeline to a certain extent. This structural design enables the silicon core tube to maintain a stable physical form when it is affected by external pressure or foundation settlement, thereby avoiding the problem of sealing failure caused by deformation.

2. Material properties ensure long-term sealing stability

The main raw material of silicon core tube is high-density polyethylene (HDPE), which is an engineering plastic with a tight molecular structure and extremely high chemical stability. It has strong anti-permeability and aging resistance. Even in a humid underground environment with high acid, alkali and salt concentrations, it can remain non-decomposed and non-deformed for a long time, ensuring that the sealing between the pipe interface and the body is not damaged.

In addition, the silicone coating on the inner wall not only has an extremely low friction coefficient, but also has certain hydrophobicity and anti-fouling properties, which can effectively prevent moisture from penetrating into the pipe, while reducing the sealing risks caused by the adhesion of mud and impurities. The advantages of this material combination enable silicon core tube to maintain good sealing performance under a variety of complex geological conditions.

3. Joint connection method improves the overall sealing effect

In addition to the advantages of the material itself, the special sealing joint technology used by silicon core tube during construction is also an important reason for its excellent sealing performance. Usually, silicon core tube is installed by hot-melt butt or electric fusion connection. Both methods can achieve seamless connection, greatly reducing the risk of leakage that may occur in traditional threaded or flanged connections.

Especially when crossing rivers, mountains, soft soil foundations and other areas prone to displacement, silicon core tube can effectively cope with the influence of natural factors such as foundation settlement and temperature difference changes through reasonable laying methods and high-quality connection processes, and maintain the sealing integrity of the entire pipeline system.

4. Ability to adapt to complex environments to enhance sealing reliability

Silicon core tube is widely used in transportation infrastructure such as roads and railways, which are often accompanied by challenges such as frequent vibrations, large temperature changes, and high groundwater levels. Thanks to the flexibility of HDPE material and the protective effect of silicone coating, silicon core tube can maintain stable physical and chemical properties in these complex environments, and will not easily crack, delaminate or loosen interfaces due to changes in the external environment.

Especially in rainy seasons or areas with abundant groundwater, the sealing advantages of silicon core tube are particularly prominent. Compared with traditional PVC pipes or steel pipes, it is not easy to cause internal rust or mildew due to water vapor intrusion, thereby extending the service life and reducing the cost of later maintenance.

5. Comprehensive advantages make it an ideal choice for communication projects

From materials, structures to construction processes, silicon core tube has demonstrated its unique advantages in sealing performance in many aspects. Coupled with its low cost, convenient laying, and strong corrosion resistance, it has become an ideal optical cable protection sleeve in the current communication network system.

In projects with extremely high sealing requirements such as along highways, urban underground pipelines, and mountain communication lines, silicon core tube has become the mainstream choice. Its wide application not only improves the overall quality of communication projects, but also provides a solid foundation for emerging needs such as future 5G base station construction and fiber-to-the-home.

The reason why silicon core tube can maintain good sealing in complex environments is inseparable from its scientific structural design, high-quality material selection, and advanced production technology. It is the combined effect of these factors that enables it to operate stably in various harsh environments and ensure the safety and smoothness of optical cable communications.

1. Structural design lays the foundation for sealing performance

Silicon core tube adopts a three-layer co-extrusion composite structure, which is extruded synchronously by three plastic extruders. The outer layer and the middle layer are mainly made of high-density polyethylene (HDPE), which has good mechanical strength and compressive resistance; while the inner layer is coated with a layer of organic silicon solid lubricant, which not only reduces the friction coefficient, but also enhances the density of the inside of the pipeline to a certain extent. This structural design enables the silicon core tube to maintain a stable physical form when it is affected by external pressure or foundation settlement, thereby avoiding the problem of sealing failure caused by deformation.

2. Material properties ensure long-term sealing stability

The main raw material of silicon core tube is high-density polyethylene (HDPE), which is an engineering plastic with a tight molecular structure and extremely high chemical stability. It has strong anti-permeability and aging resistance. Even in a humid underground environment with high acid, alkali and salt concentrations, it can remain non-decomposed and non-deformed for a long time, ensuring that the sealing between the pipe interface and the body is not damaged.

In addition, the silicone coating on the inner wall not only has an extremely low friction coefficient, but also has certain hydrophobicity and anti-fouling properties, which can effectively prevent moisture from penetrating into the pipe, while reducing the sealing risks caused by the adhesion of mud and impurities. The advantages of this material combination enable silicon core tube to maintain good sealing performance under a variety of complex geological conditions.

3. Joint connection method improves the overall sealing effect

In addition to the advantages of the material itself, the special sealing joint technology used by silicon core tube during construction is also an important reason for its excellent sealing performance. Usually, silicon core tube is installed by hot-melt butt or electric fusion connection. Both methods can achieve seamless connection, greatly reducing the risk of leakage that may occur in traditional threaded or flanged connections.

Especially when crossing rivers, mountains, soft soil foundations and other areas prone to displacement, silicon core tube can effectively cope with the influence of natural factors such as foundation settlement and temperature difference changes through reasonable laying methods and high-quality connection processes, and maintain the sealing integrity of the entire pipeline system.

4. Ability to adapt to complex environments to enhance sealing reliability

Silicon core tube is widely used in transportation infrastructure such as roads and railways, which are often accompanied by challenges such as frequent vibrations, large temperature changes, and high groundwater levels. Thanks to the flexibility of HDPE material and the protective effect of silicone coating, silicon core tube can maintain stable physical and chemical properties in these complex environments, and will not easily crack, delaminate or loosen interfaces due to changes in the external environment.

Especially in rainy seasons or areas with abundant groundwater, the sealing advantages of silicon core tube are particularly prominent. Compared with traditional PVC pipes or steel pipes, it is not easy to cause internal rust or mildew due to water vapor intrusion, thereby extending the service life and reducing the cost of later maintenance.

5. Comprehensive advantages make it an ideal choice for communication projects

From materials, structures to construction processes, silicon core tube has demonstrated its unique advantages in sealing performance in many aspects. Coupled with its low cost, convenient laying, and strong corrosion resistance, it has become an ideal optical cable protection sleeve in the current communication network system.

In projects with extremely high sealing requirements such as along highways, urban underground pipelines, and mountain communication lines, silicon core tube has become the mainstream choice. Its wide application not only improves the overall quality of communication projects, but also provides a solid foundation for emerging needs such as future 5G base station construction and fiber-to-the-home.

The reason why silicon core tube can maintain good sealing in complex environments is inseparable from its scientific structural design, high-quality material selection, and advanced production technology. It is the combined effect of these factors that enables it to operate stably in various harsh environments and ensure the safety and smoothness of optical cable communications.