Can the smooth inner wall of PE pipe reduce fluid resistance, improve transportation efficiency and save energy?

Release Time : 2025-07-30

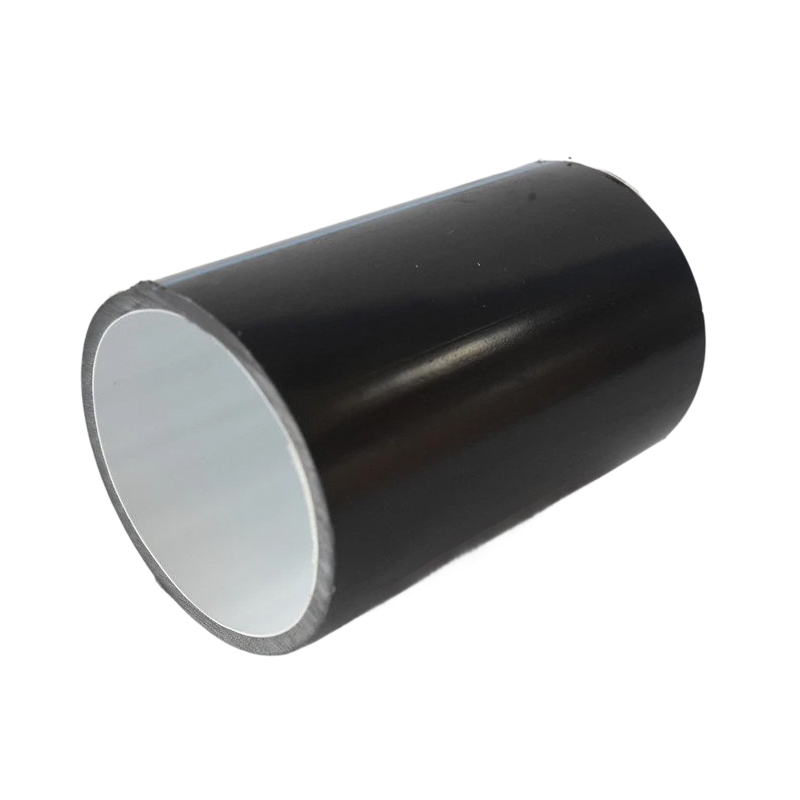

When fluid flows through a pipe, it inevitably encounters resistance from the inner wall. The magnitude of this resistance is closely related to the smoothness of the inner wall. The smoothness of the inner wall of PE pipe fundamentally changes the interface between the fluid and the pipe, creating favorable conditions for reducing fluid resistance. When fluid flows over a rough pipe wall, the uneven surface creates more eddies and disturbances. These disordered flow conditions consume additional energy, resulting in greater resistance. The smoothness of the inner wall of PE pipe reduces this disturbance, allowing the fluid to flow more smoothly through the pipe. This conserves energy that would otherwise be used to overcome the additional resistance caused by the rough surface, and this is PE pipe's core advantage in reducing fluid resistance.

This reduction in resistance directly translates into improved conveying efficiency. Under the same conveying conditions, when the resistance encountered by the fluid decreases, its flow velocity within the pipe increases, and the amount of fluid that can be conveyed per unit time also increases. For scenarios requiring continuous fluid conveying, this change means that more conveying tasks can be completed without increasing power input. For example, in water supply systems, the use of PE pipe allows water to flow more quickly through the pipe network, ensuring timely and sufficient water supply to each water point. This avoids problems such as slow flow and insufficient water supply caused by excessive resistance, a direct manifestation of improved delivery efficiency.

From an energy consumption perspective, the benefits of PE pipe's smooth inner wall are even more significant. Fluid flow in pipes requires power from equipment such as pumps, and the amount of power required is directly related to the resistance it must overcome. When resistance is reduced, the power required by the pump is also reduced, thereby reducing energy consumption. Over the long term, this reduction in energy consumption accumulates into significant savings. For example, in industrial production, large quantities of fluids need to be circulated through pipes. Using PE pipe can reduce the operating load of the circulation pump, reducing electricity consumption, extending the life of the equipment, and lowering maintenance and replacement costs, achieving energy savings and efficiency improvements in multiple ways.

Compared to other types of pipes, PE pipe offers significant advantages in reducing fluid resistance, improving delivery efficiency, and saving energy. Some traditional pipes, such as metal pipes, are prone to rust and scaling after long-term use, resulting in roughened inner surfaces and further increasing fluid resistance. Polyethylene pipe, on the other hand, offers excellent chemical stability and corrosion resistance, resists scaling, and maintains a smooth inner surface over time. This means that polyethylene pipe maintains low fluid resistance throughout its service life, continuously improving delivery efficiency and saving energy. Unlike other pipes, it requires no frequent cleaning, maintenance, or even replacement, thus reducing the additional maintenance costs and energy consumption.

This characteristic of polyethylene pipe has been widely verified and recognized in practical applications. In agricultural irrigation, using polyethylene pipe for water transportation reduces head loss along the route, enabling water to flow over longer distances, improving irrigation coverage and efficiency, and reducing the energy consumption of pumping equipment. In urban water supply systems, the use of polyethylene pipe enables water supply pressure from water plants to be more efficiently transmitted to individual users, reducing pressure loss caused by excessive pipe resistance, and ensuring stable and economical water supply. These practical examples fully demonstrate the important role of the smooth inner surface of polyethylene pipe in improving delivery efficiency and saving energy.

The smooth interior of PE pipe not only improves fluid transport efficiency and energy consumption but also indirectly reduces environmental impact. Reduced energy consumption means less fossil fuel combustion, thereby reducing emissions of greenhouse gases such as carbon dioxide, contributing to climate change mitigation. Furthermore, PE pipe's inherent light weight and ease of installation reduce energy consumption and waste generation during transportation and installation, aligning with the philosophy of green and environmentally friendly development. This environmental friendliness makes PE pipe even more valuable within the broader context of sustainable development.

With continuous technological advancements, PE pipe production processes are being optimized, ensuring and enhancing the smoothness of its interior walls. By improving production equipment and processes, manufacturers can precisely control the quality of PE pipe's interior walls, ensuring a smoother surface and further reducing fluid resistance. In the future, as energy conservation and environmental protection requirements continue to rise, PE pipe will be used more widely in various fields. Its role in reducing fluid resistance, improving transport efficiency, and saving energy will be further enhanced, making a greater contribution to sustainable social development.